Enclosures & Aluminum Profiles

The production and design of enclosures and aluminum profiles

The possibilities in the processing of enclosures and aluminum profiles by the specialists of Les Graveurs know almost no limits. Our all-round service accompanies and advises them from the first ideas and conceptions of your project to the finished end product. Your satisfaction and the quality of the manufactured products are clearly in our focus.

The possibilities in the processing of enclosures and aluminum profiles by the specialists of Les Graveurs know almost no limits. Our all-round service accompanies and advises them from the first ideas and conceptions of your project to the finished end product. Your satisfaction and the quality of the manufactured products are clearly in our focus.

Casings are usually workpieces composed of various individual parts, which for the most part act as a cover, enclosure or container. The almost infinite application possibilities of casings of all kinds make it necessary to adapt the enclosures, which are often based on standard models, to the explicit customer requirements, sometimes with the most filigree detail work. This means that a simple piece of plastic or aluminum can quickly be turned into a truly unique item with the aid of a wide variety of mechanical enclosure processing techniques, which can be used as a one-off solution for a prototype or, for example, in the private sector, or as a standardized series that can be used in a larger project.

Our service includes not only consulting, development, design and construction, but also a wide variety of machining and production processes for enclosures made of aluminum or plastics - all from a single source.

Our services around enclosures and aluminum profiles

- Enclosure machining

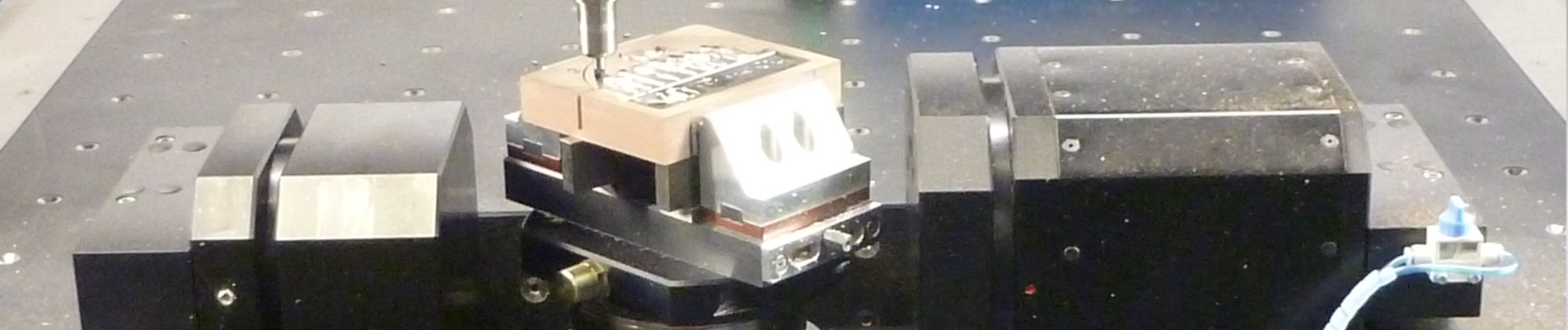

With a high degree of reliability, the utmost care and reproducible quality, we manufacture and process a wide variety of enclosure types for a wide range of applications. These include electronic enclosures, instrument enclosures, wired, wearable, handheld and wall-mounted enclosures, DIN rail enclosures, built-in enclosures, IIOT/sensor enclosures, switch enclosures or control cabinets, universal enclosures with IP65, IP66 or IP67 protection and much more.

As a matter of principle, we use aluminum, die-cast aluminum, plastic or fiberglass-reinforced plastics as materials. We consider special requests and custom-made products individually. Our team consists of a wide variety of specialists with a wide range of expertise. Thanks to the modern production technology and tooling facilities we maintain at Les Graveur, we are not only able to implement a wide variety of individual wishes, but also to maintain the consistently high quality of our products, even for small, medium or large series production. - HSC milling

One machining method with which we achieve particularly high quality is high-speed cutting (HSC milling). The cutting parameters are many times higher with this cutting technique than with conventionally applied cutting methods, which enables much cleaner and more precise results with higher surface quality. Even complex machining operations can be performed in this way in an uncomplicated and technically flawless manner.

Other advantages generated by the HSC milling method include, for example, a thirty percent time saving and the ability to machine thin-walled workpieces. Because the workpiece to be machined is heated less during HSC milling, heat-related distortion and edge zone changes are also reduced. - Drilling, milling and thread cutting

When it comes to the technical finishing touches, we rely on a great deal of sensitivity and adapt the desired enclosure entirely according to your ideas. Often, standard enclosures in particular must first be adapted for the intended target use, for example by adding openings for plug connections or terminals. Circular thread milling is also a frequently requested technique in addition to classic drilling and milling work.

Our many years of experience in these areas stand out, enabling us to respond quickly, easily and competently to any customization requests. - Labeling and engraving

At Les Graveurs, the name says it all. We are happy to individualize your enclosure with printing or lettering as well as laser engraving. Labeling can make sense for a variety of reasons - for clarity or safety reasons, or simply as part of the aesthetics. This not only optimizes the practicality of the enclosure, but also the user-friendliness and handling.

With the aid of a laser, any metals, plastics, semiconductor materials and also organic materials can be flexibly and easily marked and labeled without the use of additional substances. The surface remains undamaged and is only subjected to a color change. The laser is particularly suitable for product markings with consecutive or different numbers, serial numbers or batch markings, as well as for markings with logos, texts and the like.

FAQ – Enclosures & Aluminum Profiles

Contact Us