Injection molding

Injection molding & film insert molding

Injection molding is one of the most important and widespread molding plastic processing methods. The injection molding process has been used for the series production of components in particular since 1869: During the process, a shapeless starting material is transformed into a defined and precisely matched, solid end product.

Injection molding is one of the most important and widespread molding plastic processing methods. The injection molding process has been used for the series production of components in particular since 1869: During the process, a shapeless starting material is transformed into a defined and precisely matched, solid end product.

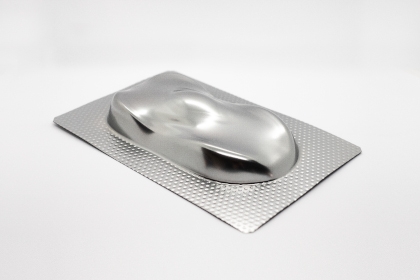

The process is usually based on a thermal process in which the materials to be processed are first melted. Then, with the aid of an injection unit, they are injected into a geometric, three-dimensional template with a shaping cavity. In this cavity, which is the heart of the process, the material solidifies into a solid through cooling or a crosslinking reaction.

The finished injection molded part can then be removed from the mold and is subsequently also suitable for further processing, for example in the area of surface finishing.

- Thermoplast Injection Molding

- Duroplast Injection Molding

- Elastomer injection molding

- Flexchrom

- Film insert molding

FIM - Film insert molding

The distinguishing feature of this process is that the optical design of the injection molded part is already achieved within the molding process in the molding body.

In a first production step, a foil is produced with the desired motif to be applied later. The screen printing process, which is also offered by our company, is particularly suitable for printing the foil.

The next step is to adapt the film to a three-dimensional shape. Vacuum thermoforming and high-pressure forming are used to optimally adapt the film with the printed design to the shape of the subsequent end product. The formed film is then inserted into the forming cavity, which serves as the forming template for injection molding in the further process.

In the final process, film insert molding is similar to the classic injection molding process: The desired material is usually thermally converted to a liquid aggregate state and injected into the hollow body. As the material cools in the mold, the design or branding applied to the film bonds with the surface of the casting, creating a leveled image directly on the perfectly shaped end product.

There are no limits to the design of the decorated film for individual branding. Both single- and multicolor motifs are available, as well as various haptic surface textures, such as matte or glossy structures and translucent effects.

Advantages of Film Insert Molding

- Efficiency

All injection molding processes are characterized by their efficient cost-effectiveness. In addition to material costs, manufacturing costs and waste products are at an extremely low level. - Rapid reproducibility

Injection molding is particularly suitable for the production of series products, as the injection mold created is suitable for permanent use over many years due to its longevity and durability. You get series-identical plastic parts that are perfectly suited for further processing - In addition, the production of castings can be implemented in a closely timed, highly automated production machinery. - Diversity

The variety of machining processes offered enables the shaping of a wide range of materials and plastics There are also no limits to the range of possible product shapes due to the unique casting technology in mold. Also with regard to branding, the FIM process in particular opens up limitless possibilities. - Direct customization

The finished injection molded part is immediately provided with an individual motif or graphic, making it ideal for rapid series production.

- Interior and exterior components in building construction

- Cladding as well as interior decoration and design elements

- Mechanical engineering and construction industry

- Components for small electronic devices and household appliances

- Production of components for defense and defense technology

- Components for vehicle interiors and the chassis

FAQ – Injection Molding & Film-Insert-Molding (FIM)

Contact Us