Embossing, pressing and punching

Embossing, pressing and punching as a service

In addition to the production of embossing tools, LES GRAVEURS offers its own metal parts production with presses and punches. With our machines we can emboss with a pressure of up to 1800 tons. In addition to the production of metal parts, our services include both the delivery of the complete series, as well as the subsequent assembly, whereby these are completely tailored to your individual requirements.

In addition to the production of embossing tools, LES GRAVEURS offers its own metal parts production with presses and punches. With our machines we can emboss with a pressure of up to 1800 tons. In addition to the production of metal parts, our services include both the delivery of the complete series, as well as the subsequent assembly, whereby these are completely tailored to your individual requirements.

Embossing, pressing and punching services

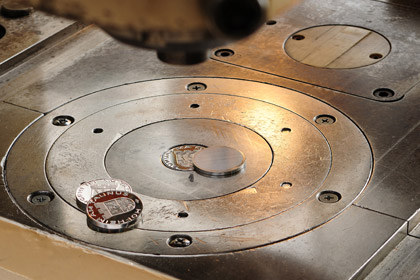

Embossing and pressing belong to the group of forming processes. In stamping, a forming tool applies a lot of pressure to a workpiece surface. The pressure causes a deformation that becomes a relief. In the skilled trades, embossing is usually done by many manual sub-steps in the surface. At LES GRAVEURS, embossing machines are mainly used. When using an embossing machine, the embossing is done automatically by means of a press in one continuous work step.

Embossing metals

The advantage of using embossing machines and punches is the optimal adaptation to your requirements. Regardless of your selected material and the desired number of pieces, the workpieces can be individually embossed. This makes it possible not only to produce one-offs, but also large series productions that all meet the same quality standards. This makes them very versatile and the range of applications is also enormous. In addition, the use of presses ensures a certain degree of precision, which is crucial for the end product.

Metal stamping

Just like coining, stamping belongs to the area of the forming process. Various materials can be formed, with the emphasis on the forming of metals. When stamping metals, flat parts are cut out of them with the help of a machine according to a certain procedure.

The process is carried out by two machine parts: the punch and the die. A punching die consists on the one hand of a punch, which is the internal shape, and on the other hand of the die, which has an opening adapted to the punch. Both machine parts are made of hardened tool steel. The die is firmly screwed to the punching machine, while the punch is guided by an accurate tool holder, which allows very precise work. The punch is driven into the die, and the forces involved break a piece out of the metal. The forces are very decisive in this process, which is why it is important that the punching machines can have them, which can be achieved by hydraulics, among other things.

The process is carried out by two machine parts: the punch and the die. A punching die consists on the one hand of a punch, which is the internal shape, and on the other hand of the die, which has an opening adapted to the punch. Both machine parts are made of hardened tool steel. The die is firmly screwed to the punching machine, while the punch is guided by an accurate tool holder, which allows very precise work. The punch is driven into the die, and the forces involved break a piece out of the metal. The forces are very decisive in this process, which is why it is important that the punching machines can have them, which can be achieved by hydraulics, among other things.

Important areas of application of the shaping processes

Embossing, pressing and punching are used as shaping processes in a wide variety of fields for different purposes.

- Metal emblems and badges

Especially in the field of marking and labeling technology, embossing and punching are widely used, such as in the production of 3D metal emblems and plaques. Through the hardened embossing die, the hydraulic presses deform the selected material. Depending on the embossing depth and size of the product, different embossing pressure is used and then can be further deformed in further steps until the desired embossing is achieved. After the embossing is complete, the workpiece is then punched into the appropriate shape. - Jewelery

Metals such as gold and silver can also be changed by high-quality pressing and stamping. This is particularly relevant for jewelry, such as earrings, pendants or rings. Very delicate and precise work is done and the piece can be processed into a high-quality unique piece. - Embossing aluminum and brass

Especially in the field of component manufacturing, the stamping of aluminum and brass is important. In a forming process, the metals are made into precise components that are adapted to your needs. During the stamping process, the stamping machines form the parts economically, resulting in the smallest possible loss of raw material and thus lower costs.

FAQ – Embossing, Pressing, and Stamping as a Service

What services does LES GRAVEURS offer in the field of embossing, pressing, and stamping?

LES GRAVEURS offers comprehensive services in the field of embossing, pressing, and stamping. These include the production of metal parts using embossing machines and hydraulic presses with a pressure capacity of up to 1800 tons. We provide complete series of metal parts and also offer assembly services tailored to your specific needs.

What is the difference between embossing and stamping?

Embossing is a forming process where a relief is applied to the surface of a workpiece under high pressure. Stamping, on the other hand, cuts or punches flat parts from a workpiece using a die and a punch. Both processes are precise and particularly suitable for metals.

What materials can be processed through embossing and stamping?

LES GRAVEURS can emboss and stamp a variety of metals, including aluminum, brass, gold, and silver. These processes are suitable for both custom-made pieces and large-scale series production requiring the highest precision. These methods are commonly used in jewelry production and in manufacturing components.

How precise are the embossing and stamping processes at LES GRAVEURS?

The precision at LES GRAVEURS is ensured through the use of hardened embossing dies and modern embossing machines. Our machines allow us to create highly detailed and precise engravings and deformations. This is particularly important in the production of metal emblems, plaques, jewelry items, and components made from aluminum and brass.

What are the application areas for embossing, pressing, and stamping?

Embossing, pressing, and stamping are used in various fields, including the production of 3D metal emblems and plaques, jewelry manufacturing (e.g., earrings, pendants, rings), as well as embossing components made from aluminum and brass. These processes enable precise and durable products for a wide range of industries.

Contact Us