Electroplating

Modern electroplating technology

To perfect the service portfolio of Les Graveurs, we were allowed to expand it in the spring with an in-house electroplating shop. We give your product a noble finish in a wide variety of colors and coatings or prepare it for further processing. You are planning an extraordinary project or want to test new processes? We are at your side as a partner and will be happy to accompany you along the way.

To perfect the service portfolio of Les Graveurs, we were allowed to expand it in the spring with an in-house electroplating shop. We give your product a noble finish in a wide variety of colors and coatings or prepare it for further processing. You are planning an extraordinary project or want to test new processes? We are at your side as a partner and will be happy to accompany you along the way.

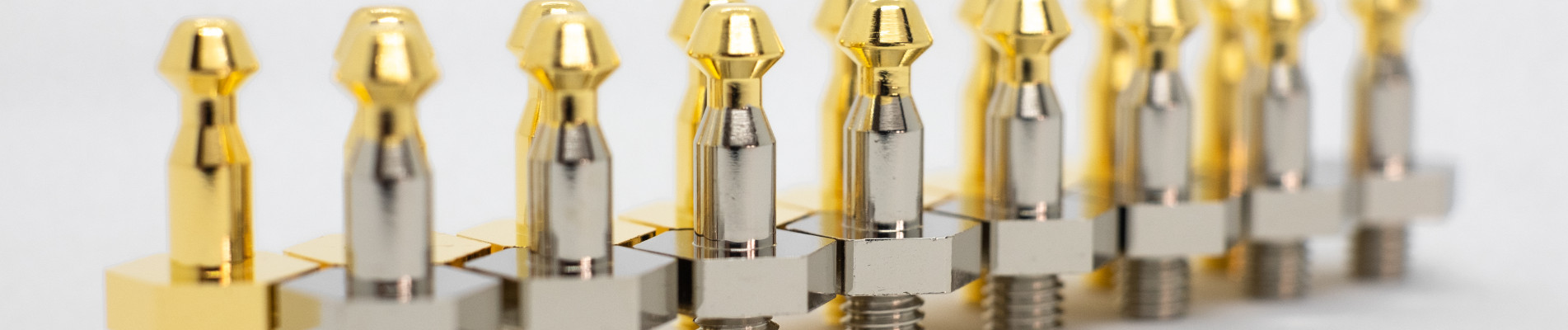

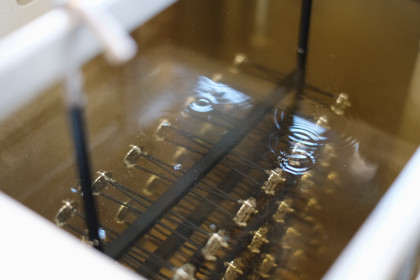

With our modern electroplating plant, we specialize in high-quality coatings of precious metals such as silver, gold and platinum, but also non-precious metals such as copper and nickel in the decorative and technical fields. Selective coatings for electrical or medical engineering or multicolored coatings of e.g. jewelry, coins and plaques can be realized by using pin electroplating or special masking techniques. We can also carry out mechanical pre-treatments such as grinding, polishing or sandblasting for you.

We coat all common base materials from non-ferrous metals such as copper, brass and their alloys, to silver and other precious metals, to stainless steels in the highest quality.

Our surface coating portfolio currently includes:

- Nickel plating (high layer thicknesses possible)

- Copper plating

- Chrome plating

- Gold plating (approx. 23.5 kt) up to 10 µm

- Direct gold plating of stainless steel

- Color gold plating (0N - 5N)

- Platinizing up to 0.5 µm

- Passivation

State-of-the-art measuring techniques help us to always ensure the best quality of the electroplated coating as well as the electrolytes used. With the help of the X-ray fluorescence measuring method (X-Ray), we determine alloys and layer thicknesses of deposited metals.

Of course, people and nature also play a major role in the use of chemical substances. We therefore only use materials that comply with the REACH regulation. Any wastewater produced is collected and completely detoxified by specialist companies. We do not discharge any substances into the basic supply and are therefore allowed to call ourselves "wastewater-free".

Of course, the use of chemical substances also plays a role in the process. Benefit from the high level of expertise and many years of experience of our electroplating team. If you have any questions about electroplating, please contact Mr.

Rouven Berger.

FAQ – Electroplating

What services does LES GRAVEURS offer in electroplating?

LES GRAVEURS offers a wide range of surface coatings through modern electroplating techniques. These include high-quality coatings made from precious metals such as gold, silver, and platinum, as well as non-precious metals like copper and nickel. Our services cover both decorative and technical coatings for industries such as jewelry, medical technology, and electrical engineering.

What materials can be coated in LES GRAVEURS' electroplating services?

At LES GRAVEURS, a wide variety of base materials can be coated, including non-ferrous metals like copper and brass, precious metals like silver, and stainless steels. We provide high-quality coatings for all common materials to meet the needs of our customers.

What types of coatings does LES GRAVEURS offer?

LES GRAVEURS offers a variety of coatings, including nickel plating (even with thick layers), copper plating, chrome plating, gold plating (up to 10 µm), direct gold plating of stainless steel, colored gold plating (0N – 5N), platinum plating up to 0.5 µm, as well as tarnish protection and passivation.

What special techniques are used in electroplating?

At LES GRAVEURS, specialized techniques such as brush electroplating and masking techniques are used to achieve selective or multicolored coatings. These methods are particularly suited for applications in electrical engineering, medical technology, as well as for jewelry, coins, and plaques.

Does LES GRAVEURS offer mechanical pre-treatments?

Yes, LES GRAVEURS offers mechanical pre-treatments such as grinding, polishing, and sandblasting. These pre-treatments ensure that the surfaces to be coated are optimally prepared for electroplating, ensuring a high-quality and even coating.

Send an inquiry to our electroplating department

To perfect the service portfolio of Les Graveurs, we were allowed to expand it in the spring with an in-house electroplating shop. We give your product a noble finish in a wide variety of colors and coatings or prepare it for further processing. You are planning an extraordinary project or want to test new processes? We are at your side as a partner and will be happy to accompany you along the way.

To perfect the service portfolio of Les Graveurs, we were allowed to expand it in the spring with an in-house electroplating shop. We give your product a noble finish in a wide variety of colors and coatings or prepare it for further processing. You are planning an extraordinary project or want to test new processes? We are at your side as a partner and will be happy to accompany you along the way.