CNC aluminum

CNC precision aluminum parts

CNC machining is a modern workpiece machining, which is characterized by its particularly good precision work. An advantage of this machining method is the diverse range of material use.

CNC machining is a modern workpiece machining, which is characterized by its particularly good precision work. An advantage of this machining method is the diverse range of material use.

LES GRAVEURS has specialized in aluminum machining, among other things. Aluminum is now ubiquitous in a wide variety of fields, from engraving to aerospace, which means that the importance of aluminum machining continues to grow.

Advantages of aluminum

The advantages of aluminum are very versatile and they are due to the different properties of the light metal.

- has a relatively low density and is thus very light

- easy processing and formability (high efficiency)

- very strong and impact resistant

- high intrinsic protection against corrosion due to an oxide layer

- good recyclability without significant loss of quality

- resistant to strong temperature changes

- hygienic lightweight metal

- electrical conductivity

CNC aluminum processing

Due to the steadily increasing consumption of aluminum, the processing of aluminum is also becoming more and more. In particular, the milling of the material is enormously important. However, when milling precision parts made of aluminum, some factors and framework conditions must be taken into account, which is why CNC machines are ideally suited for the processing.

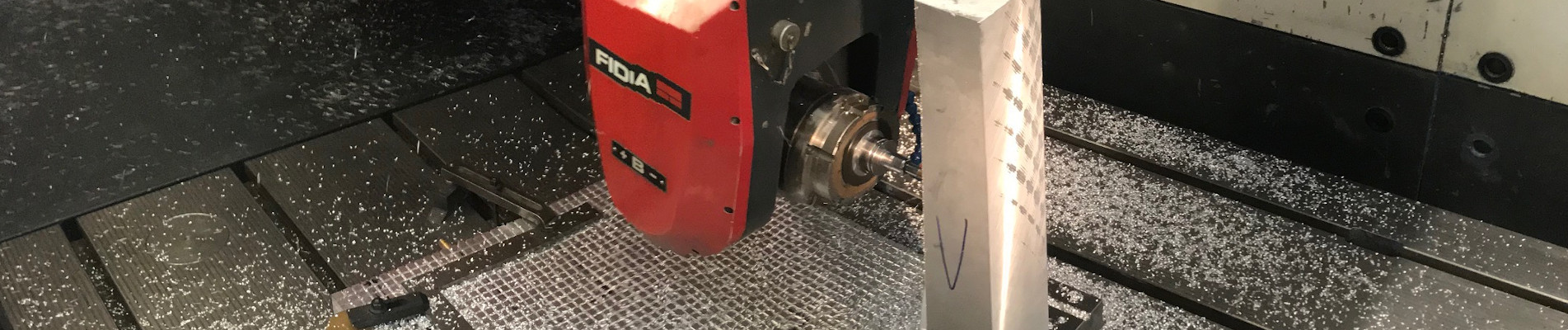

First of all, the type of cutter and tool is very important. To be able to mill aluminum, very stable and as many cutting edges as possible are necessary, otherwise they will quickly become blunt when machining the solid aluminum. Consequently, dull machines can no longer work cleanly and create a good end product. At LES GRAVEURS we use high quality CNC machines with 5-axis simultaneous milling. They are stable and are characterized by high precision here, so that a good and accurate machining can be guaranteed.

CNC machining is one of the high-speed processes. This means that aluminum is machined at high cutting speeds. A high cutting speed results in lower cutting forces, so that even thin-walled aluminum profiles can be milled almost burr-free.

Furthermore, when machining aluminum, unlike wood or steel, the material can become soft and melt due to the heat generated during milling. This makes the surface unusable for further processing. Due to the high cutting speed, however, heat is not generated as quickly and the aluminum can continue to be machined cleanly.

However, since temperature fluctuations occur during milling despite all this, we have minimum amounts of cooling lubrication on our machines. Due to the cooling, longer tool life can be achieved, so that the machining of the aluminum can also be carried out better in the long run.

First of all, the type of cutter and tool is very important. To be able to mill aluminum, very stable and as many cutting edges as possible are necessary, otherwise they will quickly become blunt when machining the solid aluminum. Consequently, dull machines can no longer work cleanly and create a good end product. At LES GRAVEURS we use high quality CNC machines with 5-axis simultaneous milling. They are stable and are characterized by high precision here, so that a good and accurate machining can be guaranteed.

CNC machining is one of the high-speed processes. This means that aluminum is machined at high cutting speeds. A high cutting speed results in lower cutting forces, so that even thin-walled aluminum profiles can be milled almost burr-free.

Furthermore, when machining aluminum, unlike wood or steel, the material can become soft and melt due to the heat generated during milling. This makes the surface unusable for further processing. Due to the high cutting speed, however, heat is not generated as quickly and the aluminum can continue to be machined cleanly.

However, since temperature fluctuations occur during milling despite all this, we have minimum amounts of cooling lubrication on our machines. Due to the cooling, longer tool life can be achieved, so that the machining of the aluminum can also be carried out better in the long run.

Applications of precision parts made of aluminum

Aluminum is now used in a wide variety of applications and its special properties, especially its low weight, make it virtually indispensable.

- Automotive industry (body, engine block, etc.)

- Construction (window frames, facades, light screens, etc.)

- Electrical engineering (conductors, sheaths and shields of cables)

- Aerospace (aluminum alloys of wings, tail, fuselage, etc.)

Our CNC work with aluminum

Our machining of precision aluminum parts is done by HSC milling, drilling, tapping and engraving of housings.

FAQ – CNC Precision Parts from Aluminum

Why is aluminum well-suited for CNC machining?

Aluminum is a versatile lightweight metal with excellent formability, making it easy to machine. It is lightweight, corrosion-resistant, recyclable, and offers good electrical conductivity. These properties make it ideal for CNC machining, where it can be precisely milled, drilled, and cut.

What are the advantages of aluminum as a material?

Aluminum offers many advantages: it is lightweight, corrosion-resistant, hygienic, and recyclable. It is also impact-resistant and can withstand significant temperature fluctuations. Additionally, aluminum is non-magnetic and a good conductor of electricity, making it attractive across various industries.

How is aluminum machined with CNC machines?

Aluminum is machined using high-speed milling techniques. The high cutting speeds minimize heat generation, preventing the material from melting or softening. At LES GRAVEURS, high-quality CNC machines with 5-axis simultaneous milling and minimal coolant lubrication are used to ensure precise machining.

What are the applications for aluminum precision parts?

Aluminum is used in many industries, including the automotive sector (body panels, engine blocks), construction (window frames, facades), electrical engineering (cable shielding), and aerospace (wings, fuselage). Its lightweight nature and corrosion resistance make it particularly sought after.

What CNC machining processes are used for aluminum?

CNC machining of aluminum includes high-speed milling (HSC milling), drilling, threading, and engraving of enclosures. These processes allow for the precise production of aluminum parts used across various industries.

Contact Us